Why is stainless steel 304 also called AISI 304 or 1.4301? A guide to the variety of names

Stainless steel is a fascinating and versatile class of materials used in a wide range of applications, from food processing and the chemical industry to architecture. Among the various types of stainless steel, grade 304 is one of the most commonly used and valued. But why does this particular stainless steel have so many different designations, such as stainless steel 304, AISI 304 or 1.4301? This article explores that question and explains the reasons for this variety of names.

Stainless steel 304: an introduction

Stainless steel 304 belongs to the group of austenitic stainless steels and is extremely popular due to its excellent corrosion resistance, mechanical properties and versatile applications. This stainless steel consists mainly of iron, chromium (around 18%) and nickel (around 8%), as well as small amounts of manganese, silicon, carbon and other elements. This alloy composition gives stainless steel 304 its unique properties, making it suitable for a wide range of applications.

The different designations:

-

Stainless steel 304: This designation is the most common and is often used in technical specifications, product descriptions and trade names. It simply refers to the composition of the material and its specific properties.

-

AISI 304: The abbreviation “AISI” stands for “American Iron and Steel Institute” and refers to an organization that sets standards for the steel industry in the USA. AISI 304 is therefore a designation according to American standards for this specific type of stainless steel. This designation is frequently used in North American markets and in technical documents prepared according to US standards.

-

1.4301: This designation is part of the European numbering system for steel grades, defined by European Standard EN 10027. The number 1.4301 corresponds to stainless steel grade 304 under European standards. It is therefore used primarily in Europe and in other regions that follow European norms.

Why so many different designations?

The variety of designations for stainless steel 304 can be traced back to several factors:

-

Regional standards: Different countries and regions have their own norms and standards for classifying steels. As a result, different designations may appear depending on which standards a particular market or application follows.

-

Industrial traditions: In some industrialized countries, certain designations have become established over time and continue to be used even though international standards exist. This can lead to a variety of names referring to the same material.

-

Trade names and brands: In many cases, manufacturers have developed specific trade names or brands for their products that differ from the pure material designations. This can cause further confusion when different brands are used for the same material.

Stainless steel 304 is widely used in a variety of applications due to its versatile properties and excellent corrosion resistance. Here are some of the most common uses of this material:

-

Food processing and catering: Due to its hygienic properties and resistance to acids and alkalis, stainless steel 304 is widely used in food processing. It is used to manufacture containers, tanks, pipelines, kitchen equipment, work surfaces and utensils.

-

Architecture and construction: In architecture, 304 stainless steel is valued for its aesthetic qualities, durability and corrosion resistance. It is used for facade cladding, railings, staircases, door and window frames, handrails, light fixtures and other building components.

-

Chemical industry: In the chemical industry, stainless steel 304 is frequently used for containers, pipelines, pumps, valves and other equipment that comes into contact with aggressive media, due to its resistance to a wide range of chemicals.

-

Medical technology and pharmaceuticals: Thanks to its hygienic properties and corrosion resistance, 304 stainless steel is used in medical technology and the pharmaceutical industry to manufacture medical devices, surgical instruments, laboratory equipment, pharmaceutical containers and implants.

-

Automotive and aerospace industries: In the automotive and aerospace industries, 304 stainless steel is used for components such as exhaust systems, body parts, fasteners and structural components due to its strength, fatigue resistance and corrosion resistance.

-

Power generation and environmental engineering: In power generation and environmental technology, stainless steel 304 is used in applications such as heat exchangers, boilers, pipelines, filters, and flue gas cleaning systems due to its resistance to high temperatures, pressure, and corrosion.

-

Shipbuilding and marine engineering: Due to its resistance to salt water and its strength, stainless steel 304 is used in shipbuilding and marine engineering for ship structures, tanks, pipelines, deck equipment, and fittings.

-

Decorative applications: Thanks to its glossy surface and modern appearance, 304 stainless steel is frequently used in decorative applications such as furniture, artworks, sculptures, watches, jewelry, and household items.

Overall, stainless steel 304 is an extremely versatile material thanks to its wide availability, excellent mechanical properties and corrosion resistance, and is widely used in many industries and applications.

Fazit:

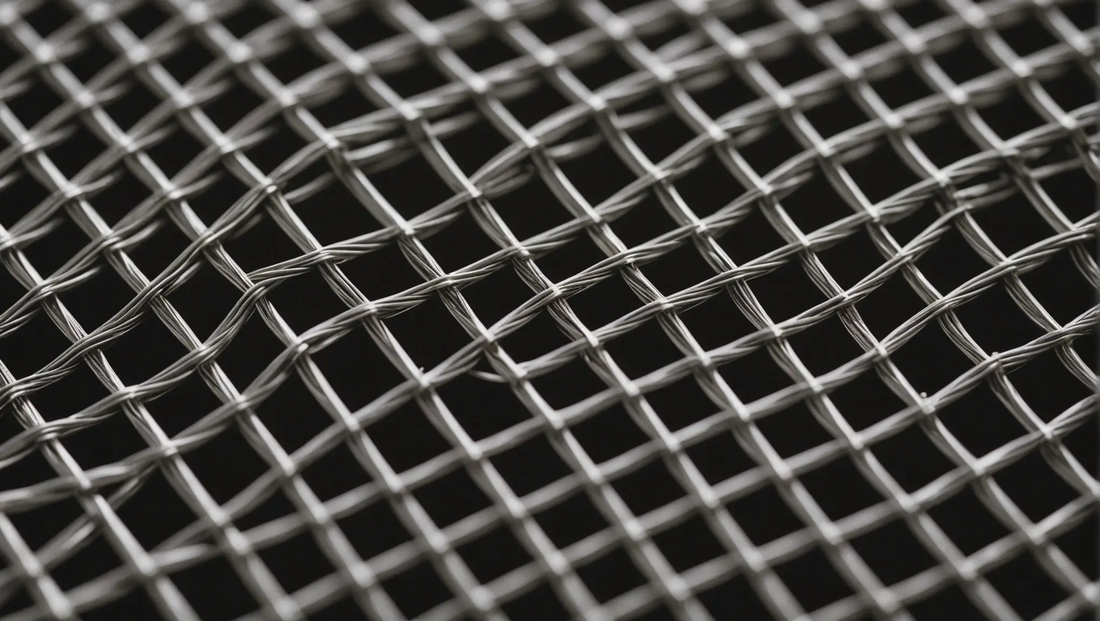

The variety of designations for stainless steel 304 such as stainless steel 304, AISI 304 and 1.4301 can be traced back to regional standards, industrial traditions and commercial practices. Despite the different names, they always refer to the same high-quality stainless steel with excellent properties and a wide range of applications across many industries. It is important to understand the different designations in order to avoid misunderstandings and ensure that the right materials are selected for specific applications. With us you will find material for wire meshes as well as welded mesh for many applications.